◆Chilling is the process to make substantial influence on its presentation, shelf life and meat structure. The better temperature controlled, the higher possible yields achieved.

◆After the carcasses have been eviscerated, they are chilled to a temperature below 4℃. The two main methods for chilling poultry are water chilling and air chilling.

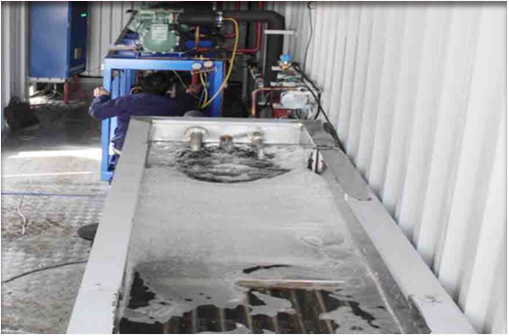

Water Pre-chilling

●Water chilling is involves a prechilling step in which a countercurrent flow of cold water is used to lower the temperature of the carcasses.

●The Water Chilling uses little floor space but offers very energy efficient. In the process, the birds are fed into the drive side of the tank, filled with chilling medium (ice water or flaked ice) to low temperature to 16℃ in the front Pre-chiller and 4℃ in the last Pre-chiller. The screws transport the birds in a counter flow through the cold water in proper time, and the air blowing system agitates them to minimize the temperature difference between birds and chilled medium.

●A specified overflow of water for each tank is required. Although this renders the chilling process very water-intensive, it helps to minimize bacterial cross-contamination by diluting the microorganisms washed off the carcasses, thereby preventing recontamination.

●Water chilling leads to an increase in poultry weight, and the amount of water gained is carefully regulated. In the United States the legal limits for water pickup are 8 percent for birds going directly to market and 12 percent for birds that will be further processed.

Air Pre-chilling

▲Air chilling is the standard in Europe. The carcasses are hung on shackles and moved through coolers with rapidly moving air. The process is less energy-efficient than water chilling, and the birds lose weight because of dehydration. Air chilling prevents cross-contamination between birds. However, if a single bird contains a high number of pathogens, this pathogen count will remain on the bird. Thus, water chilling may actually result in a lower overall bacterial load, because many of the pathogens are discarded in the water.

▲Further more, air chilling is much more expensive in cost than water chilling,an it asks bigger space and takes longer chilling time. So customers should consider about the target market requirements and project budget, and then choose the proper chilling method.

★In Raniche, Water Chilling is recommended to customers. And different sizes and quantity of Screw Pre-chiller are designed for different slaughtering capacity, for different chilling time and different carcass temperature requested. After water chilling, for better water dripping effect, a Dewatering Machine is used.

▲To decrease the temperature of the water in Screw Pre-chiller, cold water of flack ice are needed as cooling medium, which requested a unit of Water Cooling System or Flack Ice Machine.

Inquire immediately